Description

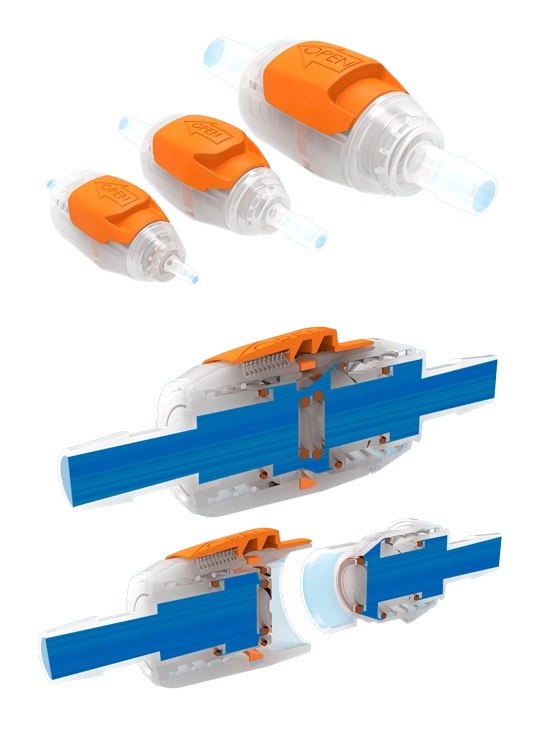

These quick couplings are separated using a slide button on the female side.

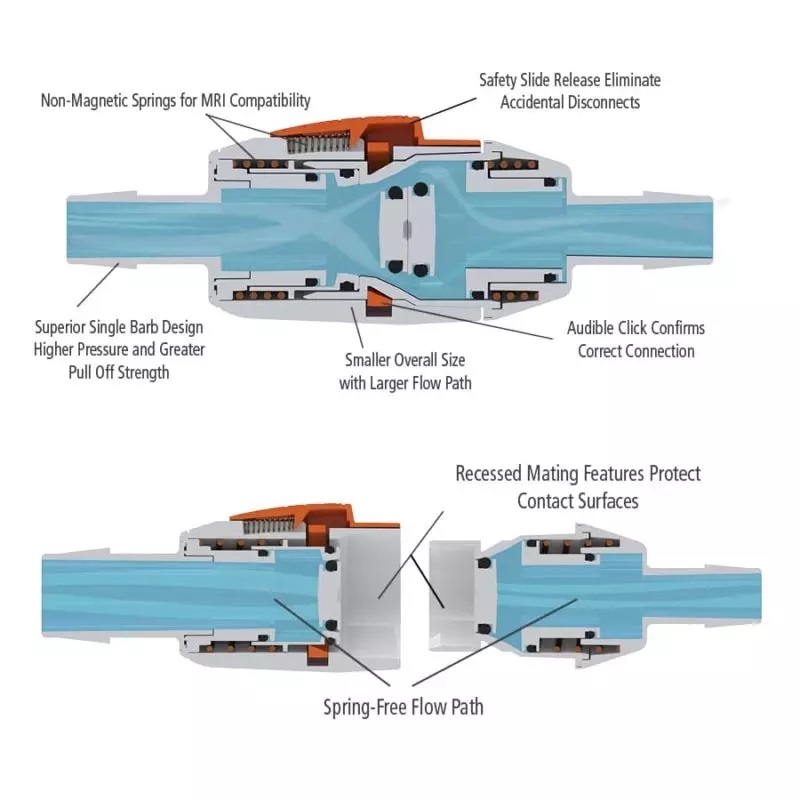

The design of these connectors allows high flow with low pressure drop and nearly no spill when disconnected.

The spring of the Small, Medium, Large and X-Large series is not in the fluid path, so the materials that get in contact with the fluid are limited to the body and o-ring materials which are selectable. There is a wide range of possible material combinations.

The design of these quick couplings is optimized for the fluid path, reducing restriction, turbulence, foaming and bubbling.

The pressure range extends from vacuum to 6.2 bar (or 4.1 bar for the Micro series).

The Micro series has minimal dimensions. Within this series, the spring is in the fluid path, but can be selected as a stainless steel version, non-metallic or non-magnetic.

The quick couplings can be combined within the series, but not across series. (For example, a combination of Small with Medium or Micro-O with Micro-V is not possible).

These connectors are used in medical technology (Life-Science), biopharmaceuticals, the printing industry and in many other applications where secure connection and disconnection must be guaranteed.

Advantages of the Sliding Latch Quick Couplings

- Spring not in fluid path (Series: Small, Medium, Large & X-Large)

- Many material combinations available

- Valved and open flow options

- Separation with nearly no spill volume

- Aseptic

- Micro series with the smallest dimensions

- Single barb design

- USP Class VI/ISO10993 compliant materials

- An audible click confirms correct connection

- Safety slide release minimizes accidental disconnects

- Can be sterilized (PP (Radiation, EtO), PVDF (Autoclave, Radiation, EtO))

- Non-magnetic spring options available

Specifications

Connections

|

1/16″, 1/8″, 3/16″, 1/4″, 5/16″, 3/8″, 1/2″, 5/8″, 3/4″, 1″

|

|---|---|

Pressure range

|

Vacuum to 6.2 bar (Micro series: 4,1 bar)

|

Temperature range

|

PP: 0°C – 71°C PVDF: 0°C – 121°C PS: -40°C – 139°C GFBN: 32°C – 232°C |

Spill volume when disconnecting

|

Small (1/8″ – 3/16″): < 0,05cc Medium (1/4″ – 3/8″): < 0,05cc Large (1/2″ – 3/4″): 0,1cc |

Body material

|

Polypropylene (PP) Polyvinylidene Flouride (PVDF) Polysulfone (PS) Glass Filled Black Nylon (GFBN) |

Sliding Button

|

Polycarbonat

|

Spring

|

Stainless steel Non-magnetic Non-metallic |

Seals

|

Buna-N EPDM Silicon Viton Non-Lubricated Silicone |

Lubricants

|

PFPE (biocompatible, inert)

|

Nut

|

PVDF (PVDF body only) Nylon (PP, PS, GFBN body only) |

Customized Quick Connections

In addition to the standard couplings, we develop customer-specific solutions with our partners, such as multi-way connectors, connectors for microfluidic chips or special sizes and designs. Manufacturing in many different plastics and sealing materials in the clean room enables usage in many different applications and industries. We would be happy to discuss your project with you and develop a coupling that is optimally tailored to your device.