Peristaltic pumps

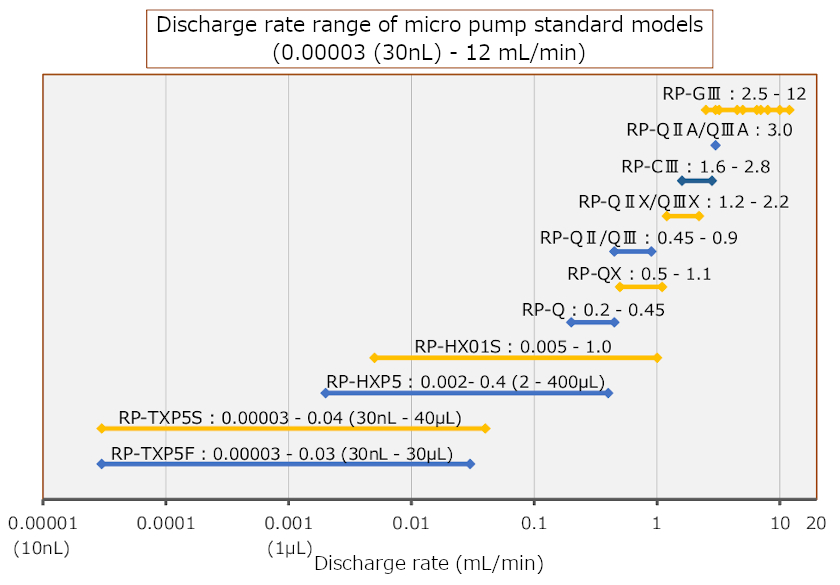

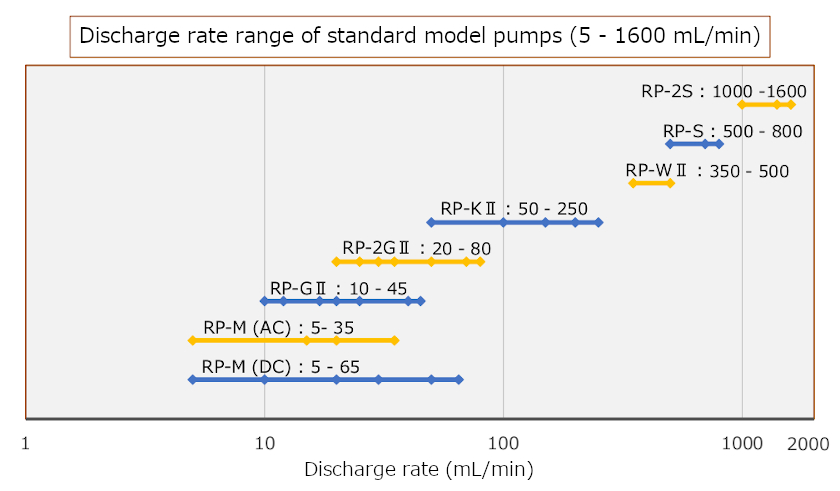

Miniature peristaltic pumps in the flor range from nl up to litre.

Product overview

Information about miniature peristaltic pumps

Peristaltic pumps are used in medical, analytical and industrial technology in a wide variety of applications. For example, as dosing pumps, feed pumps for samples in the laboratory or blood in dialysis machines, as rinsing pumps for cleaning applications or in automatic beverage dispensers.

Usually the peristaltic pumps are self-priming and push the medium in the inserted tube by pinching and moving it with one or more rollers. The roller system is usually designed to squeeze the tube at least at one point at any time, which stops the flow of the medium when the pump is switched off - like a valve. In addition to silicone tubes, there are also tubes available, which are made of resistant materials such as Pharmed®, Marprene®/Bioprene®, Norprene® or Tygon®, enabling a wide range fluids. With this type of pump it is also possible to pump higher viscosity fluids or fluids with larger particles.

Depending on the application and life-time of the tubes, it may be necessary to change the tube in certain maintenance intervals. This is possible with some pump heads by changing the tube with the head. Usually maintenance-friendly mechanisms such as flaps, rotary or snap mechanisms are developed for this purpose.

For dosing applications, peristaltic pumps with a stepper motor are particularly suitable as a drive, because individual dosing intervals can be controlled precisely . By usning less rollers with a larger diameter, the life-time of the inserted tube will increase and the maintenance intervals can be extended.

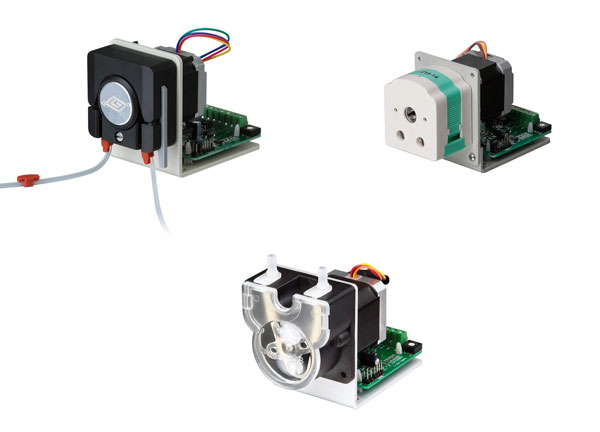

Miniature peristaltic pumps according to the Ring Pump principle

The innovative miniature peristaltic pumps, based on the Ring Pump principle, operate with a single eccentrically rotating roller. This solution enables the smallest designs and minimum flow rates in the lower microlitre range which makes it possible to use them in microfluidics.

Maintenance intervals and tube life-time significantly extended

Due to the Ring Pump mechanism, the maintenance intervals of these pumps can be significantly increased compared to standard peristaltic pumps. In applications with operating times of several minutes per day, the tubes (e.g. Norprene®, Pharmed®) of the pumps can usually be used for many years. The gentle squeezing of the tubes significantly reduces the risk of sticking, especially if the pump is operated at regular intervals. Further optimizations of the Ring Pumps enable extremely long tube operating times. Read more about this pump system in the technical information on Ring Pump peristaltic pumps. A selection of these pump types can be filtered in the list above.

Precise peristaltic pumps with stepper motor

The stepper motor-controlled peristaltic pumps enable precise control of liquid flow over a wide range. The stepper motor with a speed of up to 100 rpm can be controlled with a resolution of 0.1 rpm. The electronics required for this are optionally available and offer various control options, for example with external signals such as 4-20 mA, 0-5 V, 0-10 V, 0-10 kHz or via the RS485 interface.

Various pump heads for an easy change of the tube, allow userfriendly and quick maintenance for the end user. Furthermore, the pump heads can be equipped with a wide variety of tube sizes and tube materials - possible tube materials are, for example, silicone or PharMed®.

Multiple channels in one pump head or pump heads with up to 10 rollers for reduced pulsation offer solutions for demanding applications such as biotechnological and pharmaceutical devices.

For laboratory applications, we also offer these pumps with housing and control. An overview of these pumps and further information can be found under fluidic systems.