Inline Micro Jet Valve - fast switching

Dosing speed up to 4000 Hz

Specifications

SMLD 300

|

SMLD 300G

| |

|---|---|---|

Rated Pressure range

|

up to 20 bar

|

up to 50 bar

|

Life-time

|

up to 500 million cycles *1

|

up to 500 million cycles *1

|

Viscosity range

|

1 - 200 mPa.s

|

1 - 1000 mPa.s *2

|

Maximum flow (water, 1 bar)

|

Nozzle Ø 0.1 mm: 3.3 ml/min nozzle Ø 0.15 mm: 8 ml/min nozzle Ø 0.2 mm: 15 ml/min |

nozzle Ø 0.1 mm : 3.3 ml/min nozzle Ø 0.15 mm : 8 ml/min nozzle Ø 0.2 mm : 15 ml/min nozzle Ø 0.3 mm : 38 ml/min nozzle Ø 0.45 mm : 75 ml/min |

Minimum dosing quantity

|

less than 10 nl possible

|

less than 10 nl possible

|

Internal volume

|

25 μl

|

65 μl

|

Nozzle diameter

|

Ø 0,1 mm Ø 0,15 mm (standard) Ø 0,2 mm |

Ø 0,1 / Ø 0,15 / Ø 0,2 mm Ø 0,3 mm (standard) Ø 0,45 / Ø 0,6 mm |

Valve stroke

|

0.03 mm (standard) 0.06 mm |

0.1 mm (standard) 0.03 / 0.06 / 0.15 mm |

Bult-in filter

|

Filter 17 μm (standard), without filter on request

|

Filter 37 μm (standard), without filter on request

|

Materials in contact with the medium

|

Stainless steels: 1.4305, 1.4301, 1.4310, 1.4113 IM / PEEK, sapphire, ruby

|

Stainless steels: 1.4305, 1.4301, 1.4310, 1.4113 IM / PEEK, sapphire, ruby

|

Typical response time

|

200 μs *1

|

400 μs *1

|

Maximum dosing frequency

|

up to 4000 Hz *1

|

up to 3000 Hz *1

|

Coil resistance

|

11 Ohm

|

6 Ohm

|

Coil inductance (valve coil mounted on micro valve)

|

1.23 mH

|

0.8 mH

|

Maximum permissible coil temperature

|

100°C

|

100°C

|

Electrical connection

|

Soldering pins / 300 mm wire, tinned or with plug 2 poles Molex type 70066-176

|

Soldering pins / 300 mm wire, tinned or with plug 2 poles Molex type 70066-176

|

Recommended peak current

|

1 A / 12 VDC during 150 μs. (Current limitation required at higher voltage)

|

1 A / 12 VDC during 400 μs. (Current limitation required at higher voltage)

|

Recommended holding current

|

0.1 - 0.3 A / 1.1 - 3 V DC no time limit |

0.2 - 0.3 A / 1.2 - 2 VD C no time limit |

Weight of micro valve with coil

|

1.9 g

|

3.1 g

|

Repeatability

|

< 5% CV *1

|

< 5% CV *1

|

Minimum grid width

|

4 mm

|

6 mm

|

Dosable fluids

|

Gases, water, reagents, inks, alcohols, DMSO, MEK, other solvents, cells, liquid adhesives, plasticizers, lacquers, oils, detergents, UV adhesives, greases, pastes, etc. *1

|

Gases, water, reagents, inks, alcohols, DMSO, MEK, other solvents, cells, liquid adhesives, plasticizers, lacquers, oils, detergents, UV adhesives, greases, pastes, etc. *1

|

*1 Depending on: Configuration, surroundings and application

*2 Heated, depending on the medium, up to 15000 mPa.s

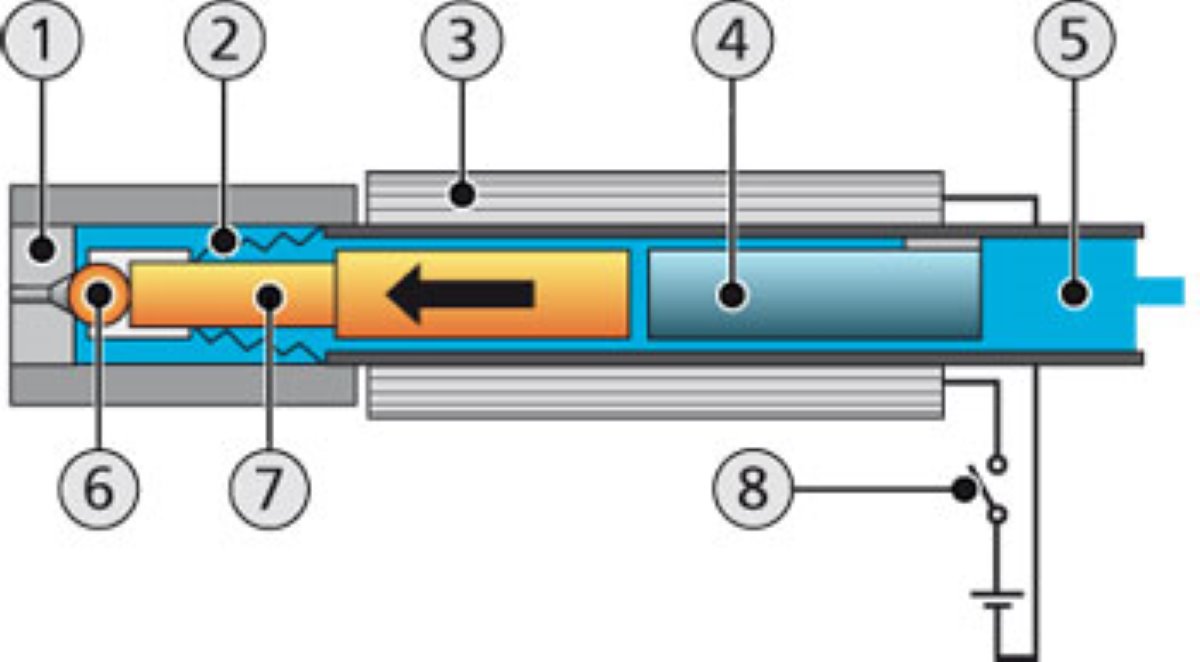

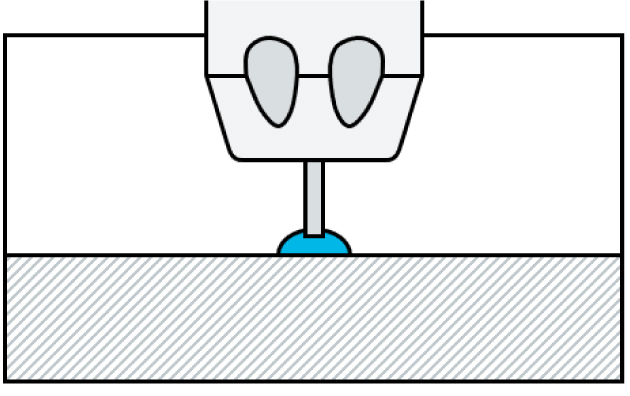

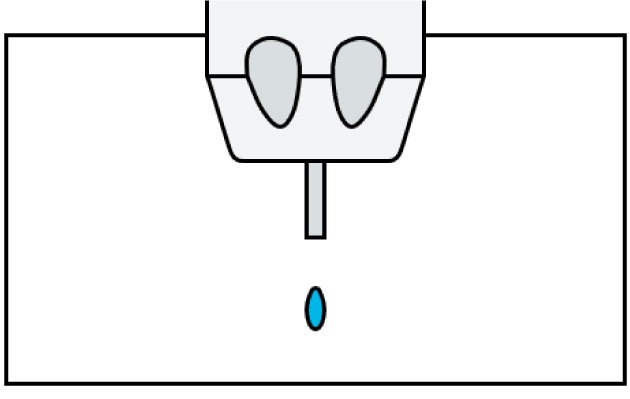

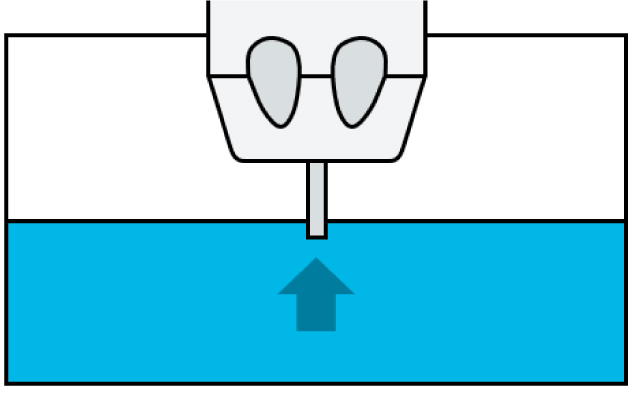

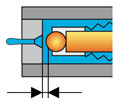

Functional principle

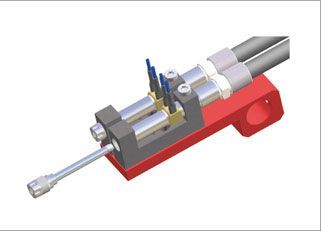

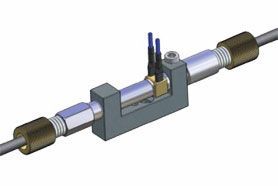

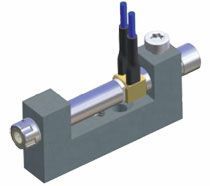

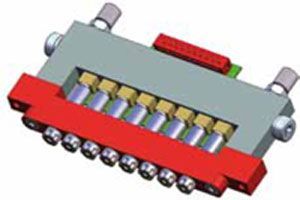

Micro-Jet valve holder

Configuration options

Fastening at the valve outlet

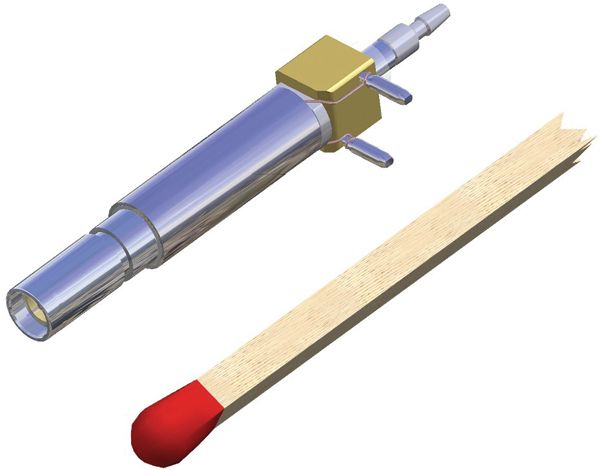

Cylinder for smallest size and narrow grid (Ø3.50mm for SMLD 300, Ø4.00mm for SMLD 300G).

Thread - Valve can be screwed into a valve holder from the front (M5 for SMLD 300, M6 for SMLD 300G).

Valve outlet

Jet for precise free jet dosing directly from the valve nozzle.

Thread for connecting attachment nozzles, pipettes and tubing to the valve outlet (10-32 UNF for SMLD 300 | ¼-28 UNF, 10-32 UNF, M5 for SMLD 300G).

Valve inlet

Manifold - suitable for the valve holders and for installation in systems with an O-ring seal (Ø1.80mm for SMLD 300, Ø2.70mm for SMLD 300G).

Tube connector for direct installation of a tubes (Ø1.20mm for SMLD 300, Ø2.30mm for SMLD 300G).

Valve assembly

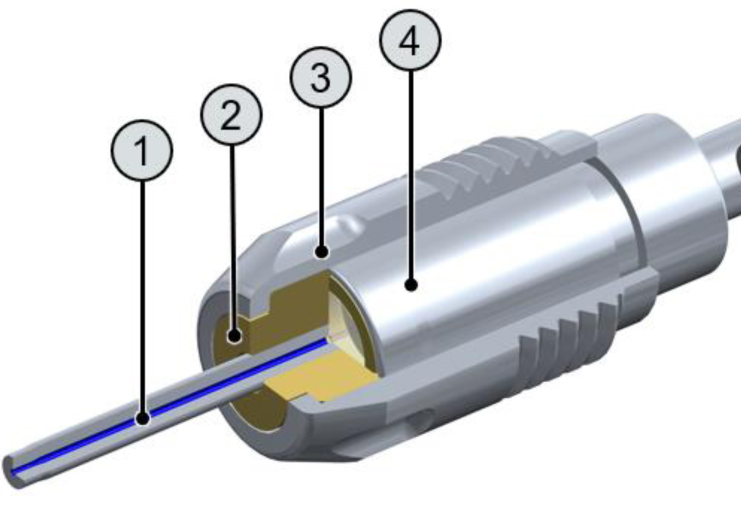

Attachment Nozzles

Contactless dosing is usually done directly from the sapphire nozzle with these micro-jet valves. However, a needle can be very useful for certain media and applications. Attachment nozzles are available for this purpose.

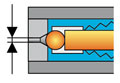

Construction & assembly

- Attachment nozzle tube (precision capillary)

- Attachment nozzle holder

- Threaded sleeve

- Micro valve with cylindric mounting type

The attachment nozzles consist of a precision capillary which is fastened in a holder with a threaded sleeve. The materials of the front nozzle are exclusively stainless steel and PEEK. This unit can simply be pushed over the valve and screwed into the valve holder. The nozzle tube is centered exactly in front of the valve nozzle and allows a practically dead volume-free connection. When the attachment nozzle is tightened, it is reliably sealed to the valve by the special shape of the parts.

Application examples

Controllers

We offer various controllers for the micro-jet valves. From individual controllers to controllers for up to 16 valves. You can find out more about this in the section of the controllers for micro-jet valves.