Description

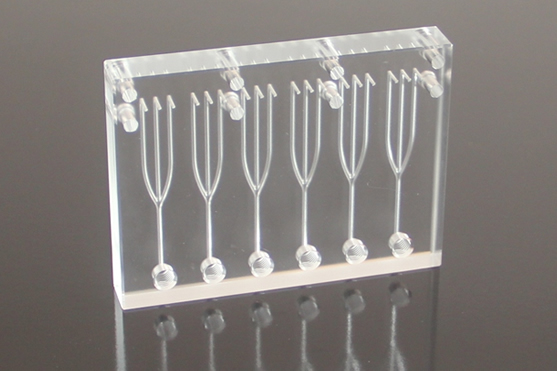

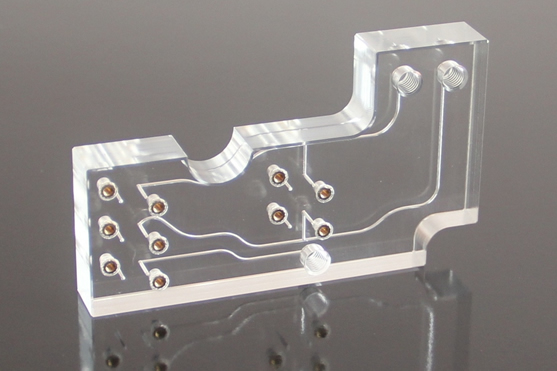

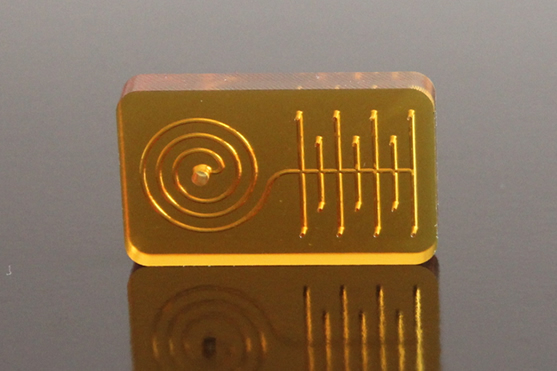

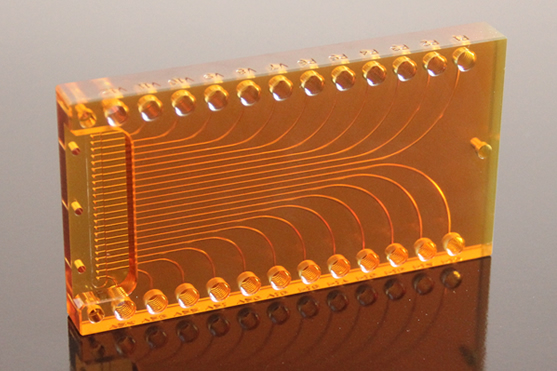

These manifolds are made by connecting multiple layers with integrated channels according to customer specifications. Unlike mechanical production, the channels can be freely designed - for example without corners and edges. By combining multiple layers, multilayer fluidic solutions can be realised. The bonding process uses no glue, so the properties of the materials used do not change and the fluidic channels will not become contaminated.

With this technique it is also possible to produce PTFE multilayer manifolds.

Applications for diffusion bonded multilayer manifolds

The diffusion bonded manifolds are used in many applications like medical technology (Life-Science), microfluidics and analytical-technology, in which complex fluidic must be implemented in a compact space. The multilayer manifolds can be made of different materials and can therefore be used in pneumatic applications with air as the fluid up to applications with aggressive liquids.

The fluidic manifold solutions are always customer-specific and can be supplied with components such as valves and pumps as tested modules that can be directly integrated. We would be happy to advise you on the design and implementation of appropriate solutions.

Materials of Fluidic-Manifold

The diffusion bonded multilayer manifolds can be multi-layered and made from the following materials for example:

- Acrylic/Plexiglas (PMMA)

- COP / COC

- Polyetherimide (PEI)

- Teflon (PTFE)