Customization of miniature valves and pumps to control high-pressure media

BMT has extensive experiences in customizing valves and pumps pressure requirements.

Below are some examples where valves and pumps are required to control high pressure media, including viscous fluids.

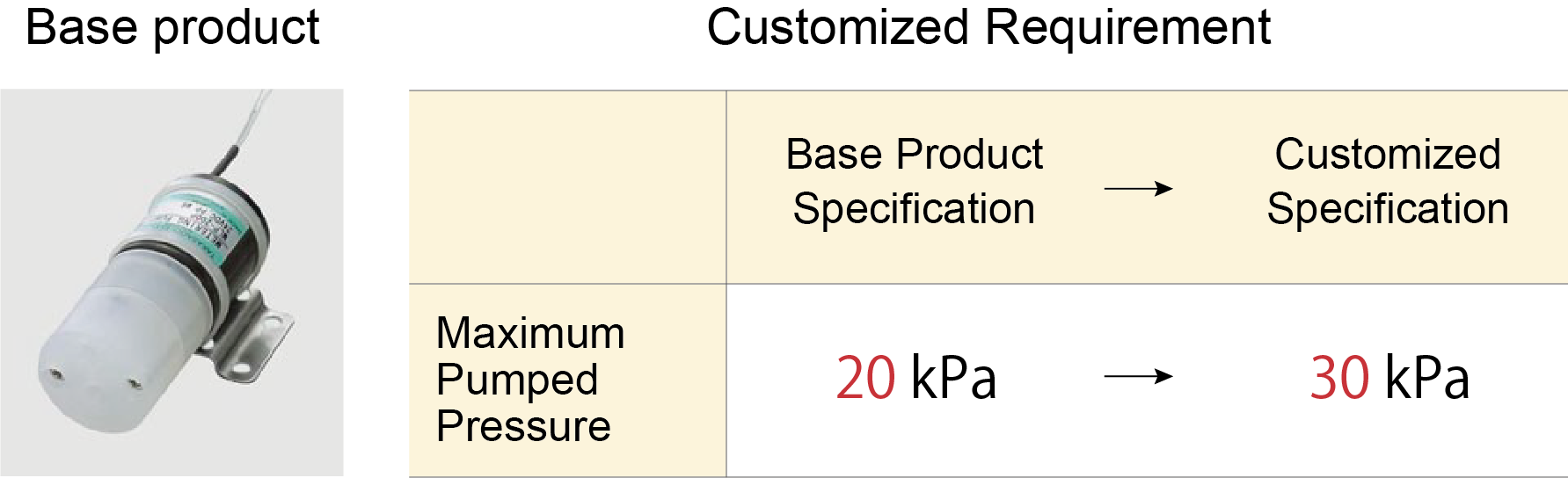

Customization of dosing pump for higher pressure range

Customization request

- Change pressure specifications

- Control the timing of fixed dispensing

Background:

- Field (Industry): Pharmaceuticals

- Application: Develop tablet manufacturing equipment.

- Problem: I want to be able to repeatedly dispense fluid with high viscosity, but the current system cannot dispense at the targeted timing.

Base Product Information

Customization

- Optimized the power balance between the spring and the actuator, and designed a pump that can discharge higher viscosity fluid (150cps) than our conventional products.

- The new product has achieved 1.5 times higher discharge pressure than the conventional product according to our inspection standards. Our customer provided very high praises on the prototype.

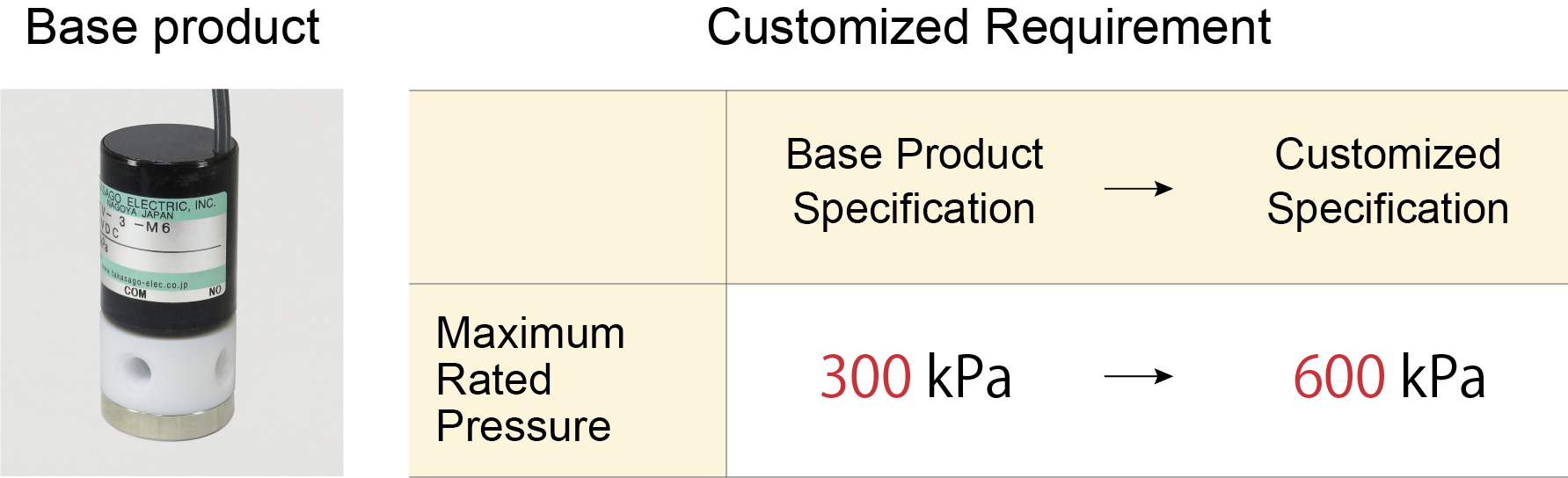

Customization of diaphragm isolation solenoid valve for higher pressure range

Customization request

- Change pressure specifications

Background:

- Field (Industry): Analysis

- Application: Developing equipment to elute heavy metals from waste in landfills.

- Problem: I am looking for a valve that can handle corrosive solutions at high pressure.

Base Product Information

Customization

- Optimized the diaphragm shape, spring, and actuator to withstand higher pressure.

- Non-metallic wetted materials are used to allow the flow of corrosive solutions.

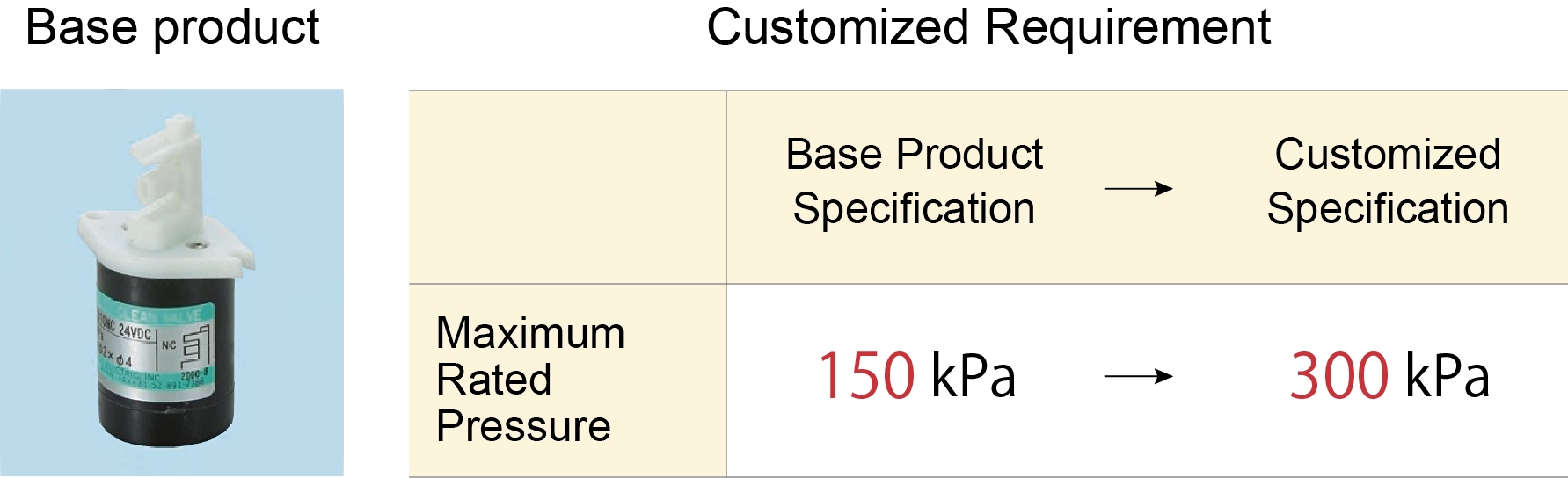

Customization of pinch pinch valve for higher pressure range

Customization request

- Change the pressure specifications

- Use the tubing of choice

- Extend the tubing life

Background:

- Field (Industry): Life Science

- Application: Developing AI-based cell sorters

- Problem: I am looking for a valve that can flow high pressure fluid using the desired tube size and material.

Base Product Information

Customization

- Optimized the power balance between the spring and the actuator to withstand the desired tube size and material, and up to the desired pressure.

- The shape of the part that holds the tubing has been optimized to extend the life of the tubing.